signs and banners

Flatbed Printing Technology

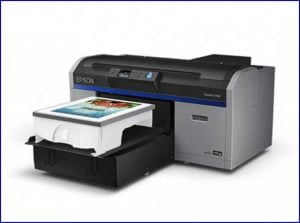

You may be familiar with printers where the print medium or substrate is fed into the printer using rollers. This is the way desktop printers work. However, there is a different type of printer where the substrate is fed into the printer using flat panels. The substrate is laid out on a flat panel, and the panel is then transferred inside the printer. These are called flatbed printers.

A flatbed has opened new opportunities. While roller-fed printers are limited to substrates such as paper and textiles, the flatbed can print on non-traditional substrates like wood, ceramics, glass, metal, leather, and much more. More importantly, flatbeds can print on 3D objects.

Flatbed Printer Technologies

Graphic Impact flatbeds rely on inkjet technology. Some of our flatbed printers make use of eco-solvent inks, and some use latex inks. Some other printers (not utilized by Graphic Impact) use authentic solvent inks, although the environmental issues created by solvent inks now force other providers to look at possible alternatives. We have found that more substrates can be used safely with our systems and are resistant to fading.

Not only do our flatbed printers print full-color graphics at impressive speeds, but white ink and clear coat are also available. The result is stunning output like never before.

Flatbed Printer Applications

Flatbed printers have changed how many people look at printing because this printer has made possible printing on substrates that cannot be accommodated by roll-fed printers or cut vinyl. Almost all of our substrates such as aluminum, coroplast, and gatorboard are fabricated using flatbed printers.

Additionally, we can customize everyday objects such as coffee mugs and laptop lids with our flatbed printers. We can also personalize interior decorating projects at a different level by designing bathroom tiles, by printing doors instead of painting them by hand, to name a few applications.

Perhaps the most critical application that many people have discovered for flatbed printers is fine art production. Aside from the fact that you can print on various printing mediums with a flatbed printer, you can also print one layer after another. This allows artists to create fine art with a lot of text that can be customized or personalized.

What Is A RIP And Why Is It Needed?

Raster image processing is the process of turning digital vector information such as a PostScript file into a high-resolution raster image.

Every image that exists in a digital electronic format is made of picture elements. At some point, all such digital image data, whether expressed as vector format data or bitmap format data, must be rendered into pixels for display on a monitor or for printing on a printer. All images, therefore, have pixels as their base. Rendering, or translating the digital data into physical output, is the most critical part of realizing such images. The term raster image processing (RIP) refers to translating digital image data into physical visual images and graphics. The software RIP interprets the page description languages and digital image data and translates the representation into a continuous tone bitmap. It then applies frequency and amplitude modulation precisely controlled by sophisticated mathematical algorithms producing the required information for the output device to function correctly.

When we want to print an advertising poster, as an example, the best results are achieved by incorporating both vector and bitmap graphics. A combination of

- Photographs – lots of colors, fixed/finite size from a digital camera. These files will be bitmaps, probably.tif or.jpg files, and large size to achieve the required resolution. Photos just can’t be easily represented as a vector graphic.

- The company logo and some simple illustrations will be small-sized files that will print smoothly at any resolution. The files use simple, non-photorealistic colors, and we may want to edit them to serve our needs. These files should be bitmaps – probably. EPS files for use in other programs.

- We will also use some fonts, which are vector files.

- The logos, illustration files, and text files will be small vector files, and they will scale infinitely to allow us to print a billboard size, and the edges will remain razor-sharp.